iLenSys Obsolescence Manager

White Paper

30 Dec 2025

Why Automation Equipment OEMs Must Treat Obsolescence Management as a Core Business Process - Not an Engineering Afterthought

Executive Summary

Automation equipment OEMs - whether building packaging machinery, robotics, CNC machine tools, test instruments, or intralogistics systems - face a growing and often invisible threat: the accelerating obsolescence of electronic components, embedded software, and system-level technologies.

Most OEMs promise 10 - 20 years of equipment support. Yet, the lifecycles of critical components such as PLCs, industrial PCs, servo drives, HMIs, processors, memory modules, displays, sensors, and operating systems are shrinking to 3 - 7 years.

This mismatch creates a structural risk that many organizations fail to quantify until it results in:

- Emergency redesigns

- Unplanned last-time-buys (LTB)

- Machine shipments halted

- Field failures and service escalations

- Lost aftermarket revenue

- Customer dissatisfaction and brand damage

This white paper quantifies the true cost of inaction - the “cost of doing nothing” - and outlines how forward-looking OEMs are adopting structured obsolescence management to prevent margin leakage, production delays, and customer service failures.

1. The New Reality for Automation Equipment OEMs

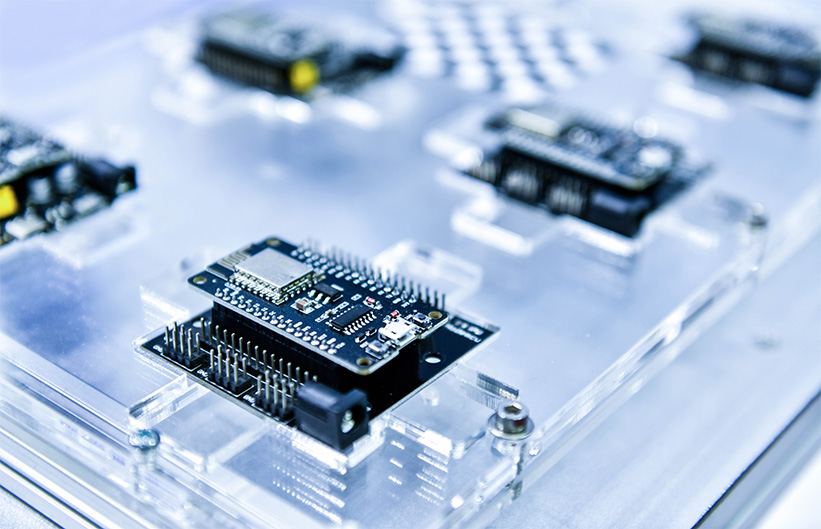

1.1 Shrinking Component Lifecycles

Electronics lifecycles shrink each year:

- Microprocessors & SoCs: 3 - 4 years

- Drives & power modules: 5 - 7 years

- Industrial PCs: 3 - 5 years

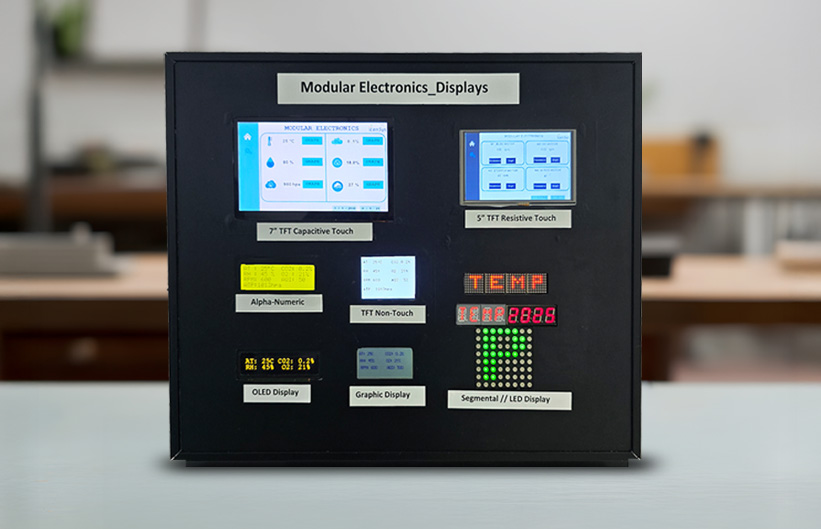

- Displays & touchscreens: 2 - 4 years

- Sensors, encoders, fieldbus cards: 4 - 6 years

1.2 Growing Expectations from End Customers

End users expect:

- 10 - 20 years of spare parts availability

- Guaranteed uptime

- Seamless field service coverage

- Backward compatibility

This creates a lifecycle gap:

It will be challenging for OEMs to meet modern customer expectations using spreadsheet-based or reactive obsolescence approaches.

2. Why Doing Nothing Is the Most Expensive Strategy

The overwhelming majority of OEMs still treat obsolescence as a reactive engineering problem - something to address only when a supplier announces an End-of-Life (EOL) or when a field failure reveals a supply shortage.

This approach creates four major categories of hidden cost.

3. Cost Category 1: Emergency Redesigns

3.1 The Trigger

An unexpected End-of-Life (EOL) event hits a critical electronic or mechanical part (MCU, FPGA, power module, relay, connector, sensor, etc.). This often results from supplier portfolio changes, process shifts, regulations, low volumes, or reallocation to higher-demand markets. It is considered “unexpected” because the OEM lacked clear lifecycle visibility, didn’t flag the part as high risk, or assumed NRND/long lead times were manageable.

Common late-stage EOL warning signs include short last-time-buy windows, sudden MOQ increases, parts becoming broker-only, extreme lead-time extensions, price spikes, or quality risks from non-authorized sources.

Procurement or supply chain usually detects the issue first through messages like “no availability,” “LTB required,” or “supplier recommends an alternate.” They escalate urgently to engineering, asking whether the part can be replaced without redesign, if alternates are approved, and what the impact is on compliance, certifications, firmware, PCB design, qualification, and customer communication. This handoff is typically rushed, as material constraints collide with engineering validation timelines.

As availability collapses, the issue quickly becomes a business disruption. Shipments may be held, customer production or service may be at risk, SLAs and contracts may be breached, and revenue recognition can slip. Costs rise due to expediting, broker purchases, or emergency redesigns, while brand trust erodes if platforms can no longer be supported.

At this point, obsolescence shifts from a technical concern to an operational and customer-impact crisis - triggering a race to secure inventory, validate alternates, redesign if needed, and protect shipments and customer uptime.

3.2 Cost Breakdown

Typical emergency redesign costs include:

- Engineering labor for redesign

- Software requalification / validation

- Machine-level testing

- Documentation updates

- Compliance recertification (if required)

- Production rework / delays

Across the industry, OEM benchmarking shows:

|

Machine Type

|

Typical Emergency Redesign Cost

|

|

Packaging machine

|

$80,000 – $250,000

|

|

CNC machine tool

|

$150,000 – $400,000

|

|

Industrial robot subsystem

|

$100,000 – $300,000

|

|

Test & measurement instrument

|

$200,000 – $600,000

|

|

Intralogistics sorter/shuttle

|

$120,000 – $350,000

|

The average cost of a single emergency redesign = $150,000 - $500,000.

3.3 Hidden costs

Project delays: lost revenue

When obsolescence-driven issues surface late, they almost always disrupt planned delivery timelines. Engineering changes triggered by EOL - such as PCB re-spins, firmware updates, requalification, or compliance re-testing - add weeks or months to schedules. During this period:

- Finished systems may sit incomplete on the factory floor due to a single missing component.

- Customer acceptance tests (FAT/SAT) are postponed, delaying milestone-based payments.

- Revenue recognition slips, impacting quarterly or annual financial targets.

- In some cases, OEMs face contractual penalties for missed delivery or late commissioning.

Unlike visible costs (new components or redesign effort), this lost or deferred revenue rarely appears directly in the engineering budget, but it has a real and material business impact.

Opportunity cost: engineering time diverted from new development

Reactive obsolescence management forces engineering teams into unplanned “firefighting” mode. Senior engineers - often the same people driving next-generation platforms - are pulled into:

- component cross-referencing and impact analysis,

- schematic/layout changes,

- firmware porting and regression testing,

- documentation updates and re-certification support.

This diversion has a cascading effect:

- New product introductions (NPI) are delayed.

- Innovation roadmaps slip while competitors move ahead.

- Engineering morale suffers as teams repeatedly revisit legacy designs instead of building new value.

The true cost is not just hours spent - it’s slowed innovation and reduced competitive advantage, which compounds over time.

Customer dissatisfaction from delays or compatibility changes

From the customer’s perspective, obsolescence issues are invisible - until they cause disruption. When shipments are delayed or products change unexpectedly:

- Customers experience uncertainty around delivery commitments.

- Field retrofits or compatibility changes may require re-validation on the customer’s line.

- Spare parts may no longer match installed systems, increasing service complexity.

- Long-term customers may question the OEM’s ability to support platforms over their promised lifecycle.

Even when technically resolved, these situations can erode trust. For industrial and automation customers - where uptime, repeatability, and long-term support are critical - perceived instability can influence future sourcing decisions.

In summary, hidden costs of obsolescence extend far beyond BOM changes. They quietly impact revenue timing, innovation capacity, and customer confidence - often making reactive obsolescence far more expensive than it appears on paper.

4. Cost Category 2: Unplanned Last-Time-Buys (LTB)

Most OEMs over-buy during LTB because they lack:

- Installed-base visibility

- Platform generation mapping

- Consumption forecasts

- Future variant/upgrade considerations

4.1 Typical LTB waste

Benchmark across OEMs shows 20 - 40% of LTB inventory ultimately becomes excess or scrapped.

Example:

An OEM buys $2M worth of drives or PCBs because a component is going EOL.

If 30% is not used:

$600,000 written off

4.2 Under-buying is just as costly

Under-buying leads to:

- Shortages

- Missed shipments

- Field service inability to repair machines

- Forced redesign (cost category 1)

Either direction = margin leakage.

5. Cost Category 3: Supply Chain Interruptions

When a part goes obsolete and there is no plan:

- Production lines halt

- Machines cannot be shipped

- Spare parts cannot be delivered

- Service teams cannibalize parts from returned machines

Typical impact:

- 3 - 8 weeks added lead time

- $5,000 - $50,000 / day cost of shipment delays

- Customer penalties and SLA failures

For system OEMs (AS/RS, robotics cells):

→ A single blocked shipment can cost $500,000+ in penalties and field labor.

6. Cost Category 4: Field Failures & Service Escalations

A machine installed 10 - 15 years ago may require:

- An obsolete drive

- An HMI panel no longer available

- A fieldbus module unsupported on newer OS versions

Service team response:

- Scramble to find gray-market parts

- Pay inflated prices (200 - 600% markup)

- Attempt risky repairs

- Inform customer that the part is discontinued

Financial impact:

- Urgent field escalations: $3,000 - $30,000 per incident

- Lost service revenue when failure cannot be repaired

- Damaged customer trust → lost future sales

7. The Total Cost of Doing Nothing

When combining all cost categories, the annual cost to a mid-size Automation equipment OEM (300 - 700 employees) typically falls between:

$2.5M - $12M per year

For large global OEMs (robotics, machine tools, packaging systems):

$15M - $50M per year

These costs persist every year unless the organization adopts structured lifecycle management.

8. Why Spreadsheets Cannot Solve Obsolescence

Most OEMs still use:

- Excel

- Email threads

- Ad-hoc meetings

- Supplier PDFs

- Engineering tribal knowledge

These tools cannot:

- Detect lifecycle risks early

- Assess impact across BOMs or installed base

- Prioritize redesign vs. LTB

- Capture workflows across Engineering, SCM, Service

- Maintain audit trail or compliance documentation

This creates organizational blind spots that amplify costs.

9. What Leading OEMs Are Doing Instead

Step 1: Introduce lifecycle intelligence

Automated monitoring of:

- Component EOL

- PCNs

- Firmware/software version risks

- Supplier roadmaps

Step 2: Create cross-functional workflows

Bring together:

- Sustaining Engineering

- Supply Chain

- Service

- Product Management

With structured decision-making:

- LTB quantity calculation

- Alternate/second-source evaluation

- Redesign approval

- Customer communication templates

Step 3: Map BOMs to installed base

Finally solve:

- Which machines use which parts

- Which customers will be impacted

- How soon service will run out of spares

10. How iLenSys Helps OEMs

iLenSys Proactive Obsolescence Management (iOM) provides:

- BoM Analysis and Risk Identification:

- 100% BoM coverage

- Clear risk prioritization based on EAU, inventory data and type of risks

- Risk Mitigation:

- Identify alternate components by evaluating circuit compatibility, application requirements, and capture form, fit and function specifications

- Work with procurement for securing inventory where appropriate

- Change Implementation:

- Implement Level 1, 2 projects with ECR/ECO, change management process

- Redesign planning. Redesign boards with 25% reduction in development time/cost

- iOM Software Tool for Proactive Obsolescence Management:

- iOM Tool to manage the complete workflow starting from risk analysis, tracking risk mitigation all the way through project completion

- Continuous monitoring

11. Conclusion: Obsolescence Is Not an Engineering Problem - It’s a Business Problem

The real question is no longer:

“Is obsolescence a risk?”

But rather:

“How much is it costing us every year to ignore it?”

OEMs that adopt structured lifecycle management reduce:

- 20 - 40% LTB waste

- 30 - 50% redesigns

- 50 - 70% service disruptions

- 5 - 10% margin leakage in spare-parts business

Automation equipment manufacturers cannot afford the cost of doing nothing.

With component lifecycles shrinking and customer expectations rising, obsolescence management must move from a reactive engineering task to a strategic capability.

iLenSys iOM delivers the intelligence, workflows, and mitigation needed to protect OEM profitability and customer trust for the next decade.