Executive Summary

The whitepaper explores the urgent need for safe and environmentally friendly chemicals and materials in today's regulatory and environmentally conscious landscape. It introduces the concept of Safe and Sustainable by Design (SSbD), emphasizing integrating safety considerations from the initial design phase through the entire product lifecycle. This approach not only enhances environmental compliance but also aligns with global goals for circular and bioeconomics, reducing pollution. Research conducted by the Ellen MacArthur Foundation suggests that businesses embracing circular economy principles are well-positioned to leverage emerging market opportunities in sustainable products and services.

Key to the SSbD framework is the establishment of rigorous assessment parameters to evaluate the safety and sustainability impacts of chemical products. By integrating SSbD into manufacturing and supply chain processes, businesses can fulfill social and environmental responsibilities, consistent with responsible business practices like those outlined in the Doughnut Model of Economics.

Embracing SSbD principles not only mitigates regulatory risks but also drives innovation in sustainable product development, contributing positively to global sustainability agendas such as the United Nations’ Sustainable Development Goals (SDGs). The whitepaper aims to guide industry leaders and policymakers in navigating the evolving landscape of safe and sustainable chemical innovation, advocating for proactive engagement in designing products that protect human health and the environment for future generations.

Introduction

The chemical industry can no longer de-prioritize developing chemicals that are safe and sustainable. Designing sustainable chemicals from inception is becoming standard practice for environmentally responsible companies. This proactive approach not only saves time and effort but also avoids the need for reactive chemical management down the line.

A survey by Deloitte indicates that consumer preference for environmentally friendly products is growing, highlighting the need for businesses to prioritize sustainability in product development as well as maintain market competitiveness and brand loyalty.

Manufacturers today must exercise heightened vigilance when dealing with chemicals. Any introduction of potential chemical hazards during manufacturing and throughout the supply chain could result in substantial fines or harm to brand reputation. Given the expanding regulations and increasing consumer demands for transparency, embracing a green manufacturing strategy for inherently safer chemicals that comply with the latest laws is crucial for long-term success.

Pioneering Sustainability: Unveiling the Safe and Sustainable by Design (SSbD) Framework

On December 8, 2022, the European Union Commission proposed the creation of a framework for assessing chemicals and materials, introducing the 'safe and sustainable by design' (SSbD) framework. This represents a substantial step forward, steering the industry toward the much-needed shift toward developing environmentally friendly and sustainable products. The framework aims to reduce or replace any potentially harmful substances per both current and forthcoming regulations.

Let us delve deeper into each phase and its significance:

(Re-)Design Phase:

This stage consists of fundamental principles to guarantee that the development procedure is directed by all-encompassing goals related to sustainability and safety. These principles function as standards for evaluating the substances and components.

Assessment Phase:

This phase–consisting of four stages–provides a structured methodology to evaluate the effects of the redesigned chemicals and materials on environmental, health, and safety factors.

This iterative approach fosters continuous improvement and ensures that chemicals and materials evolve to meet ever-changing safety and sustainability standards.

Case Studies

The Joint Research Centre (JRC) published a thorough report outlining the early adoption of the European Commission's SSbD framework. This framework centers on essential materials like plasticizers in food-contact items, flame retardants in ICT products, and surfactants in textiles. Using industry-led case studies, the report highlights the challenges faced, such as resource needs, data constraints, and the need for specialized training.

Case Study 1

A case study by Caldeira et al demonstrates how the SSbD framework can be applied to evaluate the safety and sustainability of plasticizers used in food contact materials. This study focuses on replacing the problematic chemical, DEHP, with alternatives like ATBC, DEHA, DEHT, DINCH, and ESBO. The SSbD concept embraces a life cycle approach and thus the assessment considers the entire life cycle of the plasticizer, assessing the safety and sustainability of the options through four stages: hazard assessment, production and processing safety, application safety, and environmental sustainability. Despite facing challenges such as data gaps and uncertainty regarding end-of-life scenarios, the study emphasizes the importance of risk management and highlights ESBO's potential due to its bio-based nature. Moreover, the framework incorporates an illustrative scoring system to facilitate decision-making and communication of results, ensuring a comprehensive assessment of chemicals and materials.

Case Study 2

Case study two, spearheaded by Clariant and BASF, undertakes a comparison between halogenated and non-halogenated flame retardants in ICT products.

Case Study 3

Case study three, by Novozymes, evaluates a pectate lyase enzyme in textile scouring, aiming to reduce energy and chemical usage. Industry participation highlights initial challenges like resource intensiveness and data scarcity, alongside the need for skill development.

Despite hurdles, companies recognize SSbD's potential benefits and are keen to integrate it into their R&D strategies.

The emergence of case studies within the SSbD framework has provided valuable insights, yet further studies are crucial to fully implement the framework, especially in integrating it into design and innovation processes. Stakeholders emphasize a tiered approach to ensure comprehensive coverage. Integrating Risk Assessment and Life Cycle Assessment seamlessly is vital, requiring interdisciplinary expertise. Challenges persist, including data availability for new chemicals and proprietary data, although potential solutions like predictive models and improved data-sharing platforms are being explored. Collaborative efforts to establish databases could enhance accessibility, prioritize data quality, and manage uncertainties. Effective communication across the supply chain is essential for successfully implementing SSbD.

Aligning Business Strategies with Global Sustainability Goals

The United Nations' Sustainable Development Goals (SDGs) serve as a roadmap for global progress toward sustainability. These goals, outlined in the 2030 agenda, encompass a vision for a sustainable future across various dimensions. They provide a guiding framework for policymaking at all levels and for businesses worldwide. The European Union has committed to playing a pivotal role in achieving the SDGs and aligning its development policies accordingly.

Transitioning to the SSbD framework is in line with several SDG goals such as SDG3, SDG12, and SDG14. Meeting targets under these goals involves mitigating the adverse effects of hazardous chemicals and pollutants on human health and the environment, promoting environmentally friendly management practices, and enhancing water quality through pollution reduction and responsible waste management.

Balancing Act: Integrating Social Equity and Environmental Limits in Economics

In recent times, there's been a noticeable shift in academic and political spheres toward models that give precedence to environmental sustainability over economic interests. One such illustrative concept is the "doughnut model," signaling a broader embrace of sustainability concerns. Doughnut Economics, championed by economist Kate Raworth, introduces a fresh perspective to economic thinking, aiming to ensure human prosperity while respecting the planet's boundaries. Visualized through a doughnut-shaped diagram, it delineates two key boundaries: the inner ring symbolizes essential standards of living for all, encompassing necessities like food, water, healthcare, and education; and the outer ring represents the ecological limits of the Earth, including issues like climate change, biodiversity loss, and pollution.

This model underscores the interconnectedness between social and environmental issues, advocating for a holistic approach to sustainable development. It challenges the conventional growth-centric economic paradigm by emphasizing social equity, environmental sustainability, and human well-being.

Source: https://en.wikipedia.org/wiki/Doughnut_(economic_model)

The visual representation of the Doughnut Model serves as a potent instrument for policymakers, businesses, and communities alike. It prompts a shift toward more inclusive and comprehensive approaches to economic development, where the health of both people and the planet takes precedence.

Conclusion

In summary, the SSbD framework offers a structured approach to promote the development and evaluation of chemicals and materials with a focus on safety and sustainability. Embracing the framework is no longer optional – it is a necessity for any organization seeking to future-proof its product portfolio and stay ahead of the evolving regulatory landscape. Businesses that proactively adopt these principles will be better poised to lead the charge toward a more sustainable, circular economy.

iLenSys Solutions

iLenSys offers a robust support system to assist companies in maintaining compliance with evolving regulations. Our compliance software solution streamlines product lifecycle management and ensures adherence to regulatory standards. Here's how we can help:

- We review product and Bill of Materials (BOM) files to identify components posing compliance risks.

- Our platform conducts supplier surveys to assess compliance and gather necessary documentation.

- We collaborate with suppliers and laboratories to facilitate required testing procedures.

- iLenSys provides comprehensive documentation to demonstrate product and part compliance.

- We prepare reporting documentation to streamline compliance procedures.

Additionally, you can stay informed about the latest regulatory changes and compliance tips by subscribing to our newsletter updates.

To know more about how iLensys can assist your company in staying compliant with the latest regulations, reach out to our team. Stay ahead of the curve and focus on innovation while we handle your compliance needs. Contact our experts for a consultation tailored to address your specific compliance requirements and challenges.

References and Further Reading:

- JRC Publications Repository - Safe and Sustainable by Design chemicals and materials - Application of the SSbD framework to case studies (europa.eu)

- Multiple criteria decision analysis to support the design of safe and sustainable chemicals and materials - ScienceDirect

- https://www.researchgate.net/publication/362160043_Safe_and_Sustainable_by_Design_chemicals_and_materials_Framework_for_the_definition_of_criteria_and_evaluation_procedure_for_chemicals_and_materials

- https://sdgs.un.org/2030agenda

Please Enter your Business Email to download the WhitePapers

ilensys needs the contact information you provide to us to contact you about our products and services. You may unsubscribe from these communications at any time. For information on how to unsubscribe, as well as our privacy practices and commitment to protecting your privacy, please review our Privacy Policy.

Talk to ours Product Environmental Compliance Experts.

By submitting this form, I agree to receive emails about iLenSys's products and services as per the Terms of Use. I can unsubscribe at any time via the 'unsubscribe' link in iLenSys emails or by emailing contact@ilensys.com. I also agree to the Privacy Policy.

Sign up for the latest Blogs, Case studies, Whitepapers, Webinars and Videos.

- Blogs

- Case Studies

- News and Updates

- Videos

- Webinars

- White Papers

-

- Product Environmental Compliance

- Obsolescence Management

- Regulatory & Product Safety

-

-

-

-

-

-

- New Product Development

- Mechanical Design

- FEA Validation

- Benchmarking and Value Engineering

- 3D Scanning and Reverse Engineering

- 3D Printing

-

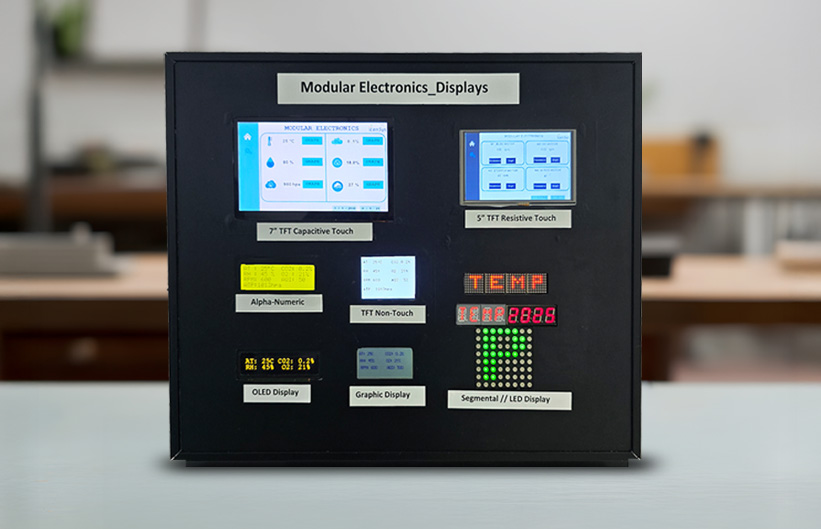

- Embedded Systems

-

- Industrial Automation

-

- Quality Assurance and Regulatory Affairs

-

- Extended Reality

- 3D Animation & Video Production

- WebGL Development

- Graphics and UI/UX Reality

-

- Technical Documentation

-

-

-

- Lab Equipment

- Medical Devices and Equipment

-

- Scientific Instruments

-

- Life Sciences

-

- Static and Mobile Equipment

-

- Material Handling Equipment

-